Double pane vacuum windows perform excellently in their properties and when they become a part of the window, they will bring us a revolutionary transformation. They offer high transmittance, low U value, are low carbon and environmentally friendly, and may qualify for government subsidies. This double vacuum glass technology offers significant advantages in energy efficiency and sustainability.

Evergreen vacuum glass supplier also provides design services with affordable vacuum double glazing costs. You can just send us an email about what you are planning for building a new structure or renovating your building. As one of the most professional vacuum insulated glass manufacturers in China, we'd like to offer our design team to give you the most professional suggestions.

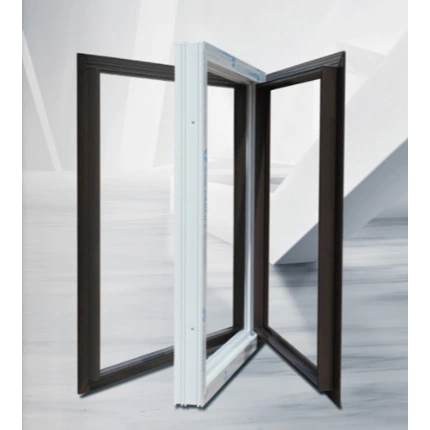

Glass | Vacuum glass solid or vacuum plus laminated or IGU ; |

Profile | UPVC or Aluminum |

Maximum size | 1500 x 3600 mm |

Special shapes | Oval, arch, triangle, half arch and more |

U-Value | 0.15-0.2 W/(m².K) |

Acoustic performance | 52 (-2;-4) Rw (C; Ctr)(dB) |

LT – Light transmission | 44-75% or above |

Low emissivity coating | Yes, in accordance with EN 1096 / EN 12150-1 / EN 14449 /EN 1279 |

1. Glass Preparation

The first step involves cutting and preparing the glass panes to the desired dimensions. The double vacuum glass surfaces must be meticulously cleaned to remove any contaminants that could affect the vacuum seal or the visual clarity of the window.

2. Edge Sealing and Spacer Placement

A key component of vacuum windows is the spacer system, which maintains a consistent separation between the two glass panes. Spacers are typically made of metal or a metal alloy and are placed around the perimeter of one glass pane. These spacers not only keep the panes apart but also contain a desiccant that absorbs any residual moisture within the unit. The edges of the glass panes are then sealed, leaving one or more small ports open for evacuating the air.

3. Evacuation

The assembled glass panes are placed in a vacuum chamber, and the air between the panes is evacuated through the ports left open in the previous step. This process creates a vacuum, significantly reducing the air molecules present between the glass panes. Achieving a high level of vacuum is crucial for the insulating performance of the window.

4. Sealing the Vacuum

Once the desired vacuum level is achieved, the ports through which the vacuum was created are sealed. This step is critical and must be performed with precision to ensure the vacuum is maintained over the lifetime of the window. The sealing material must be durable and capable of withstanding environmental stresses without degrading.

5. Final Assembly and Quality Control

After the vacuum is sealed, any additional components, such as frames or coatings, are added to the window unit. The final product undergoes rigorous quality control tests to ensure its integrity, thermal performance, and durability. These tests in vacuum glass factory may include checking the vacuum level, inspecting the seals, and assessing the overall thermal insulation properties.

6. Optional Coatings

In some cases, the glass panes may receive special coatings before the evacuation step to enhance their thermal or optical properties. Low-emissivity (Low-E) coatings are commonly applied to one or more surfaces of the glass panes to reduce heat transfer further.

Double-Pane Structure: Vacuum windows typically consist of two glass panes separated by a vacuum-sealed gap. This double-pane design helps to minimize heat transfer through the window, improving energy efficiency and thermal performance.

Vacuum Insulation: The vacuum or near-vacuum space between the glass panes serves as an insulating barrier. Since air is a poor conductor of heat, the absence of air molecules in the gap significantly reduces heat transfer through conduction and convection.

Reduced Condensation: The vacuum or near-vacuum space in vacuum windows minimizes the risk of condensation forming between the glass panes, reducing the potential for mold growth, moisture damage, and visibility obstruction.

Environmental Benefits: Vacuum windows contribute to environmental sustainability by reducing energy consumption for heating and cooling. Their superior thermal insulation properties help lower carbon emissions associated with building operation.

Customization Options: Vacuum windows can be customized to meet specific size, shape, and performance requirements for different architectural projects. They can be incorporated into various window and facade systems to achieve both aesthetic and functional goals.

Pls contact us if you have any inquire or questions, thank you.

No.12111, JINGSHI ROAD, LIXIA DIST, JINAN CITY, SHANDONG PROVINCE, CHINA