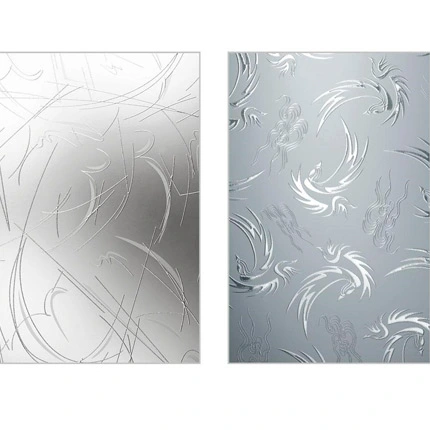

Etching Glass is a sophisticated process that involves inscribing decorative designs or patterns onto glass surfaces, creating a unique aesthetic that combines privacy with elegance. This process of our etched glass panels for sale by our etched glass manufacturer can be done through various methods, including chemical etching, sandblasting, and laser etching. These specialized techniques are often performed in a decorative glass factory where skilled artisans and advanced equipment are available.

If you want to give your room a modern and classy upgrade, decorative etched glass is a great choice. Learn glass etching cost and get art glass wholesale!

Glass Thickness | 2mm - 2.5mm - 3mm - 4-5mm - 6mm - 8mm; 10 mm - 12mm - 15mm - 19mm - 22mm - 25mm |

Glass Color | Clear, blue, bronze, green, gray, tinted reflective, ultra clear, online/offline lowe etc; |

Min size | 50x50mm; |

Max size | 3300x16000mm; |

Etching pattern | OEM; |

Extend processing | AG & AR; |

As one of the most professional etched glass suppliers and etched glass manufacturers, we provide etched glass for sale with several features.

Chemical Etching

Acid Etching: Chemical etching traditionally involves applying a substance, often hydrofluoric acid, to the glass surface. The acid reacts with the glass, creating a frosted or matte appearance in the etched areas. Acid etching can be done using stencils or resist materials to protect certain areas from the acid.

Sandblasting

Abrasive Blasting: Sandblasting, or abrasive blasting, is another method of glass etching. A stencil or resist material is applied to the glass, and then fine abrasive particles (such as sand) are propelled against the surface using compressed air. The abrasive action removes the unprotected portions of the glass, creating a frosted or textured effect.

Laser Etching

Laser Engraving: Laser etching on glass involves using a laser beam to remove or alter a thin layer of material on the glass surface. This controlled process allows for precise and detailed designs. Laser etching can create various effects, including surface etching or deeper engraving, depending on the desired outcome.

Diamond Point Etching

Hand Etching: In traditional methods, artists may use a diamond-tipped tool to etch designs directly onto the glass surface. This technique requires skill and precision, and it's often used for detailed or artistic work.

Masking and Stencils

Protection: Regardless of the etching method, certain areas of the glass need protection from the etching process. This is achieved by applying stencils, resist materials, or masking tape to the glass before etching. These protective elements ensure that only the desired areas are affected.

Frosted or Matte Finish

Resulting Appearance: The etching process typically results in a frosted or matte finish on the glass where the material has been removed. This creates a contrast between the etched and non-etched areas.

Decorative Glass: Etching is often used for decorative purposes, creating designs on glass doors, windows, mirrors, and glassware.

Customization: Etching allows for customization of glass bulk items, such as personalized gifts, glass awards, or promotional products.

Privacy and Design: Frosted glass panels created through etching can be used for privacy in bathrooms or offices while still allowing light to pass through.

Safety Measures: Depending on the etching method, safety measures may be necessary. For example, when using acids or abrasive materials, proper protective equipment such as gloves and goggles should be worn.

Etching glass from our decorative glass factory provides a creative and versatile way to add decorative elements to glass surfaces, making it a popular choice in various artistic, architectural, and functional applications.

Pls contact us if you have any inquire or questions, thank you.

No.12111, JINGSHI ROAD, LIXIA DIST, JINAN CITY, SHANDONG PROVINCE, CHINA