The process of applying an indium tin oxide (ITO) coating to glass typically involves sophisticated techniques to ensure a uniform, high-quality layer. The most common methods for depositing ITO coatings are sputtering and chemical vapor deposition (CVD). Below is an overview of these processes:

Sputtering is a physical vapor deposition (PVD) technique widely used for applying ITO coatings. The process involves the following steps:

a. Preparation

Cleaning: The glass substrate is thoroughly cleaned to remove any contaminants that could affect the adhesion and quality of the ito coating.

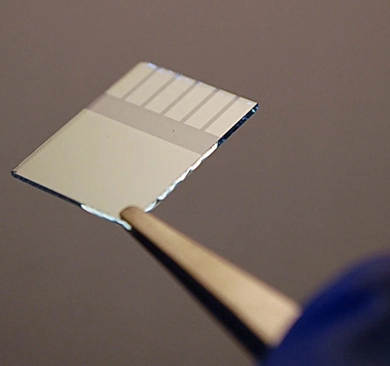

Masking: If specific areas of the glass need to remain uncoated, masking materials are applied.

b. Sputtering Process

Vacuum Chamber: The glass substrate is placed in a vacuum chamber to minimize contamination and ensure a controlled environment.

Target Material: A target made of indium tin oxide is placed in the chamber.

Plasma Generation: An inert gas, usually argon, is introduced into the chamber and ionized to create a plasma.

Sputtering: The plasma ions bombard the ITO target, causing atoms to be ejected from the target material.

Deposition: These ejected atoms then travel through the vacuum and deposit onto the glass substrate, forming a thin, uniform ITO layer.

c. Post-Processing

Annealing: The building glass for sale may be annealed (heated) to improve the crystallinity and conductivity of the ITO layer.

Quality Control: The coated glass undergoes inspection and testing to ensure it meets the required specifications.

CVD is another method used for depositing ITO coatings, particularly for applications requiring high uniformity and conformity. The process involves:

a. Preparation

Cleaning: Similar to sputtering, the glass substrate is cleaned to remove contaminants.

Masking: Masking materials are applied if needed.

b. CVD Process

Reaction Chamber: The glass substrate is placed in a reaction chamber.

Precursor Gases: Gaseous precursors containing indium, tin, and oxygen are introduced into the chamber.

Chemical Reaction: The precursors react at the surface of the glass substrate, typically at elevated temperatures, to form a thin film of ITO.

Deposition: The ITO layer is deposited uniformly across the glass surface.

c. Post-Processing

Annealing: The decorative glass wholesale may be annealed to enhance the properties of the ITO layer.

Quality Control: The final product is inspected and tested to ensure it meets the desired specifications.

Thickness Control: The thickness of the ITO layer can be precisely controlled by adjusting the deposition parameters, such as time, temperature, and gas flow rates.

Uniformity: Both sputtering and CVD can achieve high uniformity, which is crucial for applications like touchscreens and displays.

Customization: The process parameters can be tailored to achieve specific electrical and optical properties, such as sheet resistance and transparency.

The ITO coating process on glass involves advanced deposition techniques like sputtering and CVD to achieve a high-quality, uniform conductive layer. Each method has its own advantages and is chosen based on the specific requirements of the application. Proper preparation, precise control of deposition parameters, and thorough post-processing are essential to ensure the performance and durability of the ITO coated glass.