When it comes to optics and precise reflections, a standard mirror often doesn't meet the stringent requirements. This is where the First Surface Mirror, also known as an fs mirror, comes into play. Specially designed to provide accurate and undistorted reflections, first surface mirrors are indispensable in fields like laser optics, astronomy, and even fine arts. Let's explore what sets an fs mirror apart and how it can be practically applied in various domains.

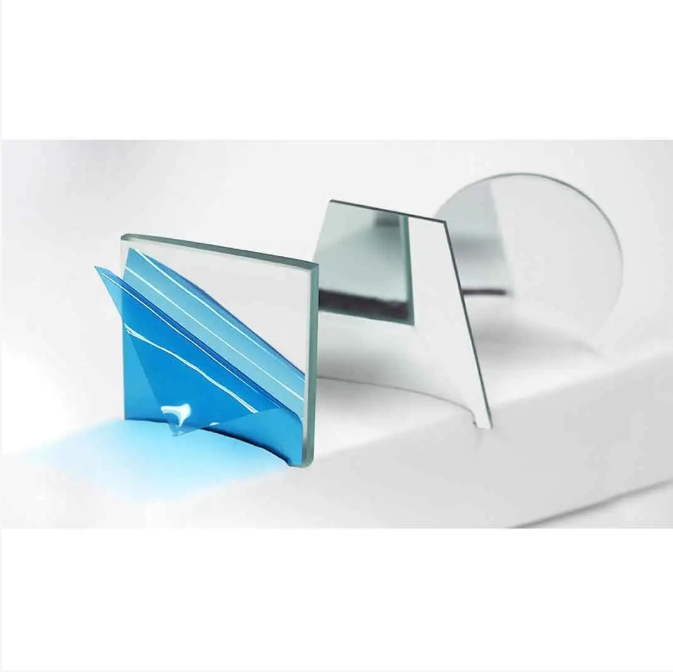

A first surface mirror, sometimes referred to as a front surface mirror or fs mirror, has the reflective coating on the top (first) surface of the glass substrate. Unlike traditional mirrors, which have the reflective coating on the back side of the glass, a front surface mirror eliminates issues with secondary reflections and refraction. This results in a mirror that provides a much higher fidelity reflection, making it an ideal choice for high-precision applications.

The technical construction and purpose of a first surface mirror distinguish it from more commonly found back surface mirrors. The reflective surface is often made of aluminum, silver, or other metals, and this surface is susceptible to physical damage as there is no protective glass layer over it. Hence, proper care is crucial to maintain its high-quality reflection.

As a custom architectural glass, the fs mirror is utilized in various applications where the utmost reflective accuracy is needed:

1. Optical Devices: Utilized in cameras and telescopes for accurate reflection and transmission of light without distortions.

2. Laser Systems: Crucial for directing and manipulating laser beams in industrial and scientific settings.

3. Projection Systems: Employed in projectors to direct light with precision, ensuring high-quality image outputs.

4. Medical Instruments: Used in devices requiring precise optical pathways, such as certain diagnostic equipment.

5. Fine Arts and Photography: Useful for artists and photographers who need undistorted and sharp reflections.

6. Virtual Reality (VR) and Augmented Reality (AR): Forms integral components for creating a seamless and immersive user experience.

Cleaning a first surface mirror, given its exposed reflective coating, requires more cautious handling compared to a standard mirror. Here's a step-by-step guide:

1. Use Soft Materials: Always use a microfiber cloth or lens cleaning tissue to avoid scratching the surface.

2. Apply Gentle Pressure: Excessive force can damage the reflective layer. Gentle wiping is sufficient to remove most dirt and fingerprints.

3. Cleaning Solution: If needed, use a mild, non-abrasive cleaning solution, such as diluted isopropyl alcohol or a specialized optical cleaner. Apply the solution to the cloth, not directly on the mirror.

4. Avoid Touching with Bare Hands: Oils and dirt from your fingers can contaminate the reflective surface, so wearing gloves is advisable.

5. Blow Dust Off: For removing loose dust, use a can of compressed air. Make sure to hold the can upright to avoid liquid propellant from being sprayed.

Proper cleaning prolongs the lifespan and maintains the performance of an fs mirror.

Creating a first surface mirror is a meticulous process, often requiring specialized equipment and conditions. Here's an overview of the steps involved:

1. Selection of Substrate: High-quality glass or another stable material is selected as the base.

2. Surface Preparation: The substrate is cleaned and polished to remove any imperfections that could affect the reflective quality.

3. Deposition of Reflective Coating: Using methods such as vacuum deposition or sputtering, a thin layer of reflective material (like aluminum or silver) is deposited on the front surface.

4. Protective Overcoat: Sometimes, a very thin protective overcoat may be applied to increase durability but only if it does not affect the reflection quality.

5. Quality Control: The finished fs mirror undergoes rigorous testing to ensure it meets the required standards for reflectivity and surface accuracy.

The importance of first surface mirrors cannot be overstated in fields that necessitate undistorted and highly accurate reflections. From improving the quality of optical devices to ensuring precision in laser systems, fs mirrors offer unparalleled performance that other types of mirrors simply can't match. Although they require careful handling and cleaning, the benefits they bring to various technological and artistic applications make them indispensable.

Evergreen Glass specializes in high-quality first surface mirrors, providing building glass for sale with precision and reliability you need for your specialized applications. Whether you seek to enhance the optical performance of your devices or achieve impeccable reflections in your artistic endeavors, first surface mirrors from Evergreen Glass can meet your highest standards.