Glass is an exquisite material used in numerous applications, from functional pieces like windows and mirrors to decorative items such as vases and sculptures. Two popular techniques to enhance the aesthetic appeal of glass are laser etching and engraving. While these terms are often used interchangeably, they entail distinct processes and outcomes. Understanding the difference between laser etching and engraving is crucial, especially if you are considering customizing glass items. This article will delve into these processes, highlighting their unique aspects and benefits.

At its core, both glass etching and engraving involve creating designs on the surface of the glass. However, the methods and results differ significantly.

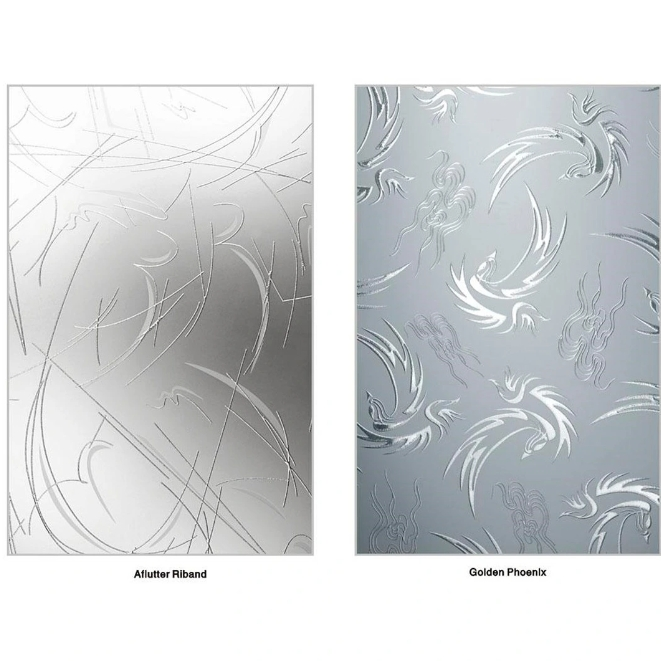

Glass Etching is a process that removes a thin layer of the glass surface to create a frosted appearance. This can be achieved through chemical etching using acids or, more commonly today, through laser etching. Laser etching uses a focused laser beam to produce intricate designs by altering the surface texture. The key characteristic of etched glass is its smooth, matte finish.

Glass Engraving, on the other hand, involves physically cutting into the glass surface. Traditionally, this was done using rotary tools or diamond-tipped instruments. Modern methods leverage advanced lasers to achieve high precision and detail. The primary difference is that engraving removes a small amount of material to create deep, three-dimensional patterns or text on the glass. The engraved lines are usually more pronounced and textured compared to etched designs.

The advent of laser technology has revolutionized both engraving and etching processes. Evergreen Glass, a leader in custom glass solutions, employs state-of-the-art laser equipment for unparalleled precision and versatility.

Laser etching operates by directing a laser beam onto the glass surface, which heats and removes a micro-thin layer, resulting in a frosted pattern. This technique allows for detailed imagery, logos, and intricate designs to be replicated with high accuracy.

Laser engraving, however, works slightly differently. The laser penetrates deeper layers of the glass, cutting away pieces of the material to produce a more textured and lasting imprint. This method is suitable for more durable applications where depth and durability are crucial, such as awards, signage, and customized glassware.

Evergreen Glass, as one of professional etched glass suppliers in China, uses the finest lasers calibrated for optimal performance to achieve both etching and engraving with exceptional detail and consistency.

The custom laser engraved glass offers several distinct advantages, making it a favored choice for various applications:

1. Durability: Engravings are deeply etched into the glass, making them resistant to wear and tear. This proves particularly useful in functional items like commemorative plaques and awards, where longevity is essential.

2. Detail and Precision: The advanced laser technology used by Evergreen Glass ensures that even the most complex designs are rendered accurately. This makes it suitable for fine details in custom designs and intricate patterns.

3. Three-Dimensional Feel: The depth achieved in engraving adds a tactile dimension to the design, giving it a more substantial and professional appearance. This is ideal for creating a premium feel for products and decorations.

4. Customizability: Laser engraving allows for a high degree of customization, perfect for unique gifts, corporate branding, or personalized home décor items.

While engraving has its merits, etching glass also brings several benefits that might make it a preferred choice for different scenarios:

1. Aesthetic Appeal: The smooth, frosted finish of etched glass has a sophisticated, elegant look. It works wonderfully for decorative pieces, such as vases and tabletop items, where a subtle touch is desired.

2. Versatility: Laser etching can be performed on various glass types and thicknesses, making it a versatile technique for a multitude of applications, from small cosmetic enhancements to large-scale projects.

3. Intricacy: Etching provides the ability to achieve highly intricate and detailed designs that might be too delicate for engraving. This makes it suitable for fine artwork and delicate patterns.

4. Non-Invasive: Since etching does not penetrate deeply into the glass, it is less likely to compromise the structural integrity of the glass item. This makes it ideal for objects where maintaining strength and safety is essential.

Both laser etching and engraving offer unique ways to enhance the aesthetic and functional value of glass items. The choice between the two depends on the desired outcome—whether you prefer the smooth, frosted finish of etched glass or the sharply detailed, three-dimensional designs of engraved glass.

Evergreen Glass factory continues to use the latest laser technologies to push the boundaries of what’s possible in glass customization, ensuring that whether you're seeking the elegance of etched glass or the durability and precision of engraved glass, you’ll receive impeccable results. From glass block laser etching to intricate engraved decorations, the possibilities are boundless.